Powering operational excellence

Powering

operational excellence

Powerhouse Resources is a maintenance and operation partner, supporting our critical infrastructure clients to return their assets to full productivity.

Powerhouse Resources was established in 1999, to provide outage support to the nuclear sector for the maintenance, repairs and overhaul of their pumps and mechanical seals.

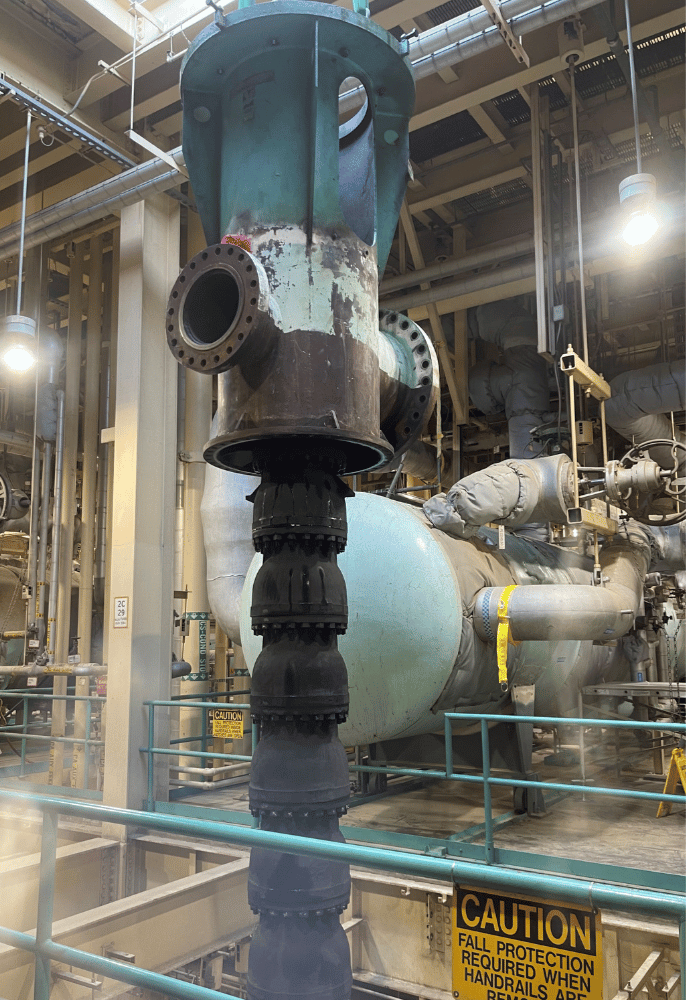

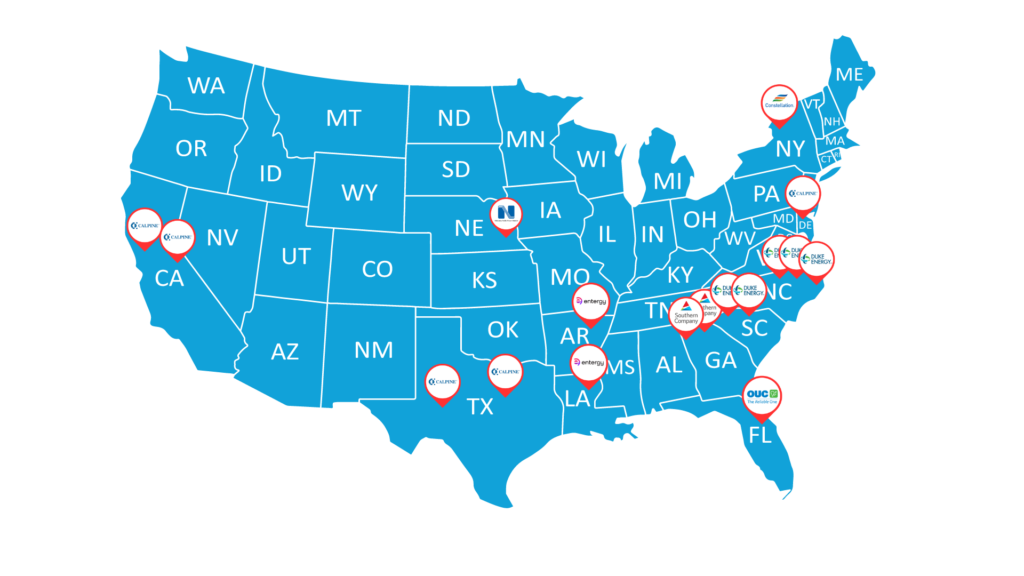

Since then, the team has grown, and we now provide support around the year for critical infrastructure clients. Providing emergency response, technical oversight, outage and maintenance support across the asset. We provide expert capability in rotating equipment, mechanical seals, heat exchangers, turbines, refueling and electrical and mechanical maintenance. We hold a strong base in the Southeast and are continuously expanding our portfolio across the United States

Our customers continue to come back to us because they can trust us to remove their technical and project concerns. They know we will always provide world-class service due to our years of industry experience as a service provider and as operators of assets ourselves. This hands-on experience means we always recognize the issues, requirements and concerns allowing us to deliver a rapid response with zero defects, safety issues or need for rework. So, when Powerhouse Resources work on assets our clients know we are removing the risks of critical failure or delayed operations. Beyond our scope Powerhouse Resources often step in to address other emergent issues on-site.

Powerhouse Resources provides our clients a single point of contact within our leadership team, so they receive a committed service while our dynamic business model ensures they get the people they need when they need them for an optimized schedule, and reduced costs and risks

Powerhouse Resources is a maintenance and operation partner, supporting our critical infrastructure clients to return their assets to full productivity.

Powerhouse Resources was established in 1999, to provide outage support to the nuclear sector for the maintenance, repairs and overhaul of their pumps and mechanical seals.

Since then, the team has grown, and we now provide support around the year for critical infrastructure clients. Providing emergency response, technical oversight, outage and maintenance support across the asset. We provide expert capability in rotating equipment, mechanical seals, heat exchangers, turbines, refueling and electrical and mechanical maintenance. We hold a strong base in the Southeast and are continuously expanding our portfolio across the United States

Our customers continue to come back to us because they can trust us to remove their technical and project concerns. They know we will always provide world-class service due to our years of industry experience as a service provider and as operators of assets ourselves. This hands-on experience means we always recognize the issues, requirements and concerns allowing us to deliver a rapid response with zero defects, safety issues or need for rework. So, when Powerhouse Resources work on assets our clients know we are removing the risks of critical failure or delayed operations. Beyond our scope Powerhouse Resources often step in to address other emergent issues on-site.

Powerhouse Resources provides our clients a single point of contact within our leadership team, so they receive a committed service while our dynamic business model ensures they get the people they need when they need them for an optimized schedule, and reduced costs and risks.

This means that as a client of Powerhouse Resources you get:

Optimized cost management with strong planning, management, control and accountability

Quicker turnarounds for optimized productivity

Transparency throughout the jobsite with confidence, assurance and risk mitigation

Guaranteed exceptional safety standards and personnel training

Ensured regulatory compliance delivered by our industry experts

Maximized asset performance driven by expert let maintenance strategies

Our Culture

At Powerhouse, we have cultivated a team with deep expertise to deliver, for our customers, what we think others have not. Bridging this gap is core to our mission in prioritizing world class services.

We all recognize the safety risks that we and our clients are exposed to, further elevating the value of teamwork and strong decision-making as keys to success.

As a team we work together and continue to evolve to better the industry. We embody the importance of bringing the ‘old’ with the ‘new’, many of our team members and clients have been with us since the beginning, while we consistently seek out new talent to help us meet the increasing needs of the marketplace. Whether a seasoned or new Powerhouse team member – your experience and values are critical to maintaining our culture of customer first, zero rework, with uncompromising excellence in skills, delivery and performance.

Our work

Qualifications & Certifications

- OEM trained and qualified senior technicians

- NCCCO certified crane operators and riggers

- All field technicians OSHA 10 and Powersafe certified

- Follow the EPRI rigging process for industrial best practices

- Utilize Industrial Operators Handbook as our benchmark for human performance

- Decades of senior civilian plant leadership experience, from craft personnel to executive leadership

Our Experts

Joe Klecha

Chairman of Board/Managing Partner

Joe brings extensive knowledge with over 30 years of power plant experience, having worked his way up from Navy Nuclear Operator to Senior Executive. He leads Powerhouse as it grows to support more clients benefitting from our skilled craft and expert led services.

Joe has hands on experience leading the operations, maintenance and construction of nuclear generation facilities throughout the US. Joe has also held a leading position, supporting technology and data investments as companies embarked on a new era of digital transformation, to better manage their assets, and build plants for the future.

Joe has sat on many advisory boards and is a recognizable face having delivering many industry keynotes – discussing the optimization of assets to maximize productivity and return on investment.

- Global Energy & Utility Director Cohesive / Bentley Systems

- Licensed General Contractor – Top Tier (FL, AL, GA, NC, and SC)

- Vice President Site Operations Vogtle 3&4 (Southern Company)

- Vice President Construction / Project Director Vogtle 3&4 (Southern Company)

- Director Fleet Operations (CFAM) Duke Energy

- Director of Operations Vogtle 1&2 Southern Company

- Work Management CFAM / Industry AP-928 Vice Chairman (Southern Company)

- Licensed Senior Reactor Operator / Shift Manager (Constellation Energy)

- Navy Nuclear Operator – USS Nebraska / Submarine NR-1

- BS Nuclear Engineering Technology – Thomas Edison State College

- Masters in Business Administration – Duke University

- Senior Nuclear Plant Manager (SNPM) – Institute Nuclear Power Operations 2013

Alfred Meadows

President of Operations

Al is a widely recognized face across the industry, with over 40 years plant experience. He has been instrumental within Powerhouse Resources for many years, shaping the organization to what it is today. Al is very clear on this mission to always deliver right first time, with a safe quality service, achieved by always putting the customer first.

Al utilizes his experience to lead the Field Operations Team to ensure that we always hold true to our promise and maintain our excellent track record. Beyond managing our service delivery, Al is also well known across the industry for the support he delivers to in house teams with training programs so that our clients have the strongest team in the field.

- 5 years Siemens O&M Direct Engineering support for CCPP 2×1 South America

- 5 years with Flowserve Field Service / QRC / TSG Project Manager

- Flowserve O&M N-Seal Certified

- Project Management with both Siemens and Flowserve

- Certified Field Representative for Hyundai Heavy Industrial (HHI) Turbo Machinery Pumps

- TECHSTAR certified Human Performance Master Instructor

- Master’s Degree, (Webster University) Organizational Security Management

- Bachelor of Science Degree (Thomas Edison State College) Nuclear Engineering Technology

- Retired Master Chief Machinists Mate, US Navy (Submarines)

Shayne Tenace

Senior Vice President - Operations

Shayne is a widely reputable Program Manager who has led many large programs across the industry. It was Shayne’s years of delivering successful programs within the industry that brought him into Powerhouse.

Shayne leads the turbine capability within the business. He provides expert teams to ensure turbines are repaired, updated or maintained to an exceptional standard, providing the team and experience to ensure a safe and optimized outage.

- 33 Years Power Plant experience

- 20 Years Project Management Leadership experience (Over $2B project size)

- Bruce Power Senior Director of Construction for major component replacement project

- Bechtel Site Manager qualified – Vogtle Unit 3 Area Construction Manager

- Construction Manager / Engineering Manager / Project Manager for DC Cook Turbine Recovery Project

Nick Anderson

General Manager Rotating Equipment and Mechanical Seals

Nick leads our rotating equipment team, delivering maintenance and operational support for mechanical pumps and seals, with over 15 years of experience specializing in this capability. Nick is a regular supporting our customers through their outage season and responding rapidly to emergent cases with the impactful team that ensures their plant is back running to capacity quickly.

- 15+ Years as Pump/Motor and Seal Replacement Specialist

- Subject Matter Expert on Feed Pumps, Feedwater Pumps, Booster Pumps, Recirculating Pumps, and Circulating Water Pumps

- Flowserve Memphis Hot Shop, Lead Technician

- Certified OEM Flowserve N-Seal Technician

- Supervisor Training

- Various Pump and Seal Qualifications

- General Electric Gas Turbine Certified

- General Electric Steam Turbine Certified

Scott Holliday

General Manager Electrical and I&C

Scott is a new addition to the team, having been known by Powerhouse for a long time. With over 30 years of experience working in the electrical field for plants, he leads the team to deliver services to support with electrical and I&C operations and maintenance.

Scott is the person to call for an expert to assess and rectify an issue whether for planned outage, in an emergency situation or simply to deliver routine maintenance and operational capability.

Having worked in the field for many years and experienced many different scenarios Scott is very specific about the skills and expertise he brings to site, and as such delivers training courses to ensure our client always receives exceptional service and results.

- 30+ Years in the Electrical Field (Nuclear, Fossil, Hydro, Gas)

- Retired Duke Energy Traveling Bus and Breaker Supervisor

- Certified Electrical Testing

- Electrical Craft Training Supervisor

- Turnkey Project Manager

- Bus and Breaker Specialist

- Turbine Generator Expert

- Expert in all Phases of Turbine/Generator Maintenance

- Familiar with all Duke Energy Sites/Work Scope

- Supervisor Training Course Completion

- Degree in Mechanical Engineering

- Diploma in hvac and refrigeration

Chad Bracken

General Manager Reactor Services

Chad has joined our team to head up reactor services. Chad has a wealth of experience supporting clients to achieve their outcomes, ensuring the plant is up and running efficiently and effectively. Chad and his team are the people to go to for expert support during a refueling program.

- Field Services Leadership, Supervision, Management, and Project Management 19+ years, with 17+ of those years in the Nuclear Industry successfully completing 135 assignments, 102 of them being outage support at customer sites (2007- present)

- Business Development, Process Improvement, and Strategic Planning

- Project Management over Augmented Reality Application Projects and Training Development

- Project Management of Outages and Dry Fuel Storage/Dry Cask Storage Campaigns

- Westinghouse – Motor, Pump, Seal Specialist, and Advisement

- Westinghouse – RCPM RVI Specialist

- Industrial Pump, Motor, and Seal Specialist

- GE – RST, IVVI, Vessel Tech, and Under Vessel Qualifications/Experience

- Reactor Head Replacement and Modification Projects

- Reactor Services – Head Area Maintenance, Reactor Disassembly/Reassembly, Refuelling Support Operations, Steam Generator Primary/Secondary Manways, and Pressurizer Manways Support.

Our Experts

Joe Klecha

Chairman of Board/Managing Partner

Joe brings extensive knowledge with over 30 years of power plant experience, having worked his way up from Navy Nuclear Operator to Senior Executive. He leads Powerhouse as it grows to support more clients benefitting from our skilled craft and expert led services.

Joe has hands on experience leading the operations, maintenance and construction of nuclear generation facilities throughout the US. Joe has also held a leading position, supporting technology and data investments as companies embarked on a new era of digital transformation, to better manage their assets, and build plants for the future.

Joe has sat on many advisory boards and is a recognizable face having delivering many industry keynotes – discussing the optimization of assets to maximize productivity and return on investment.

- Global Energy & Utility Director Cohesive / Bentley Systems

- Licensed General Contractor – Top Tier (FL, AL, GA, NC, and SC)

- Vice President Site Operations Vogtle 3&4 (Southern Company)

- Vice President Construction / Project Director Vogtle 3&4 (Southern Company)

- Director Fleet Operations (CFAM) Duke Energy

- Director of Operations Vogtle 1&2 Southern Company

- Work Management CFAM / Industry AP-928 Vice Chairman (Southern Company)

- Licensed Senior Reactor Operator / Shift Manager (Constellation Energy)

- Navy Nuclear Operator – USS Nebraska / Submarine NR-1

- BS Nuclear Engineering Technology – Thomas Edison State College

- Masters in Business Administration – Duke University

- Senior Nuclear Plant Manager (SNPM) – Institute Nuclear Power Operations 2013

Alfred Meadows

President of Operations

Al is a widely recognized face across the industry, with over 40 years plant experience. He has been instrumental within Powerhouse Resources for many years, shaping the organization to what it is today. Al is very clear on this mission to always deliver right first time, with a safe quality service, achieved by always putting the customer first.

Al utilizes his experience to lead the Field Operations Team to ensure that we always hold true to our promise and maintain our excellent track record. Beyond managing our service delivery, Al is also well known across the industry for the support he delivers to in house teams with training programs so that our clients have the strongest team in the field.

- 5 years Siemens O&M Direct Engineering support for CCPP 2×1 South America

- 5 years with Flowserve Field Service / QRC / TSG Project Manager

- Flowserve O&M N-Seal Certified

- Project Management with both Siemens and Flowserve

- Certified Field Representative for Hyundai Heavy Industrial (HHI) Turbo Machinery Pumps

- TECHSTAR certified Human Performance Master Instructor

- Master’s Degree, (Webster University) Organizational Security Management

- Bachelor of Science Degree (Thomas Edison State College) Nuclear Engineering Technology

- Retired Master Chief Machinists Mate, US Navy (Submarines)

Shayne Tenace

Senior Vice President – Operations

Shayne is a widely reputable Program Manager who has led many large programs across the industry. It was Shayne’s years of delivering successful programs within the industry that brought him into Powerhouse.

Shayne leads the turbine capability within the business. He provides expert teams to ensure turbines are repaired, updated or maintained to an exceptional standard, providing the team and experience to ensure a safe and optimized outage.

- 33 Years Power Plant experience

- 20 Years Project Management Leadership experience (Over $2B project size)

- Bruce Power Senior Director of Construction for major component replacement project

- Bechtel Site Manager qualified – Vogtle Unit 3 Area Construction Manager

- Construction Manager / Engineering Manager / Project Manager for DC Cook Turbine Recovery Project

Nick Anderson

General Manager Rotating Equipment and Mechanical Seals

Nick leads our rotating equipment team, delivering maintenance and operational support for mechanical pumps and seals, with over 15 years of experience specializing in this capability. Nick is a regular supporting our customers through their outage season and responding rapidly to emergent cases with the impactful team that ensures their plant is back running to capacity quickly.

- 15+ Years as Pump/Motor and Seal Replacement Specialist

- Subject Matter Expert on Feed Pumps, Feedwater Pumps, Booster Pumps, Recirculating Pumps, and Circulating Water Pumps

- Flowserve Memphis Hot Shop, Lead Technician

- Certified OEM Flowserve N-Seal Technician

- Supervisor Training

- Various Pump and Seal Qualifications

- General Electric Gas Turbine Certified

- General Electric Steam Turbine Certified

Scott Holliday

General Manager Electrical and I&C

Scott is a new addition to the team, having been known by Powerhouse for a long time. With over 30 years of experience working in the electrical field for plants, he leads the team to deliver services to support with electrical and I&C operations and maintenance.

Scott is the person to call for an expert to assess and rectify an issue whether for planned outage, in an emergency situation or simply to deliver routine maintenance and operational capability.

Having worked in the field for many years and experienced many different scenarios Scott is very specific about the skills and expertise he brings to site, and as such delivers training courses to ensure our client always receives exceptional service and results.

- 30+ Years in the Electrical Field (Nuclear, Fossil, Hydro, Gas)

- Retired Duke Energy Traveling Bus and Breaker Supervisor

- Certified Electrical Testing

- Electrical Craft Training Supervisor

- Turnkey Project Manager

- Bus and Breaker Specialist

- Turbine Generator Expert

- Expert in all Phases of Turbine/Generator Maintenance

- Familiar with all Duke Energy Sites/Work Scope

- Supervisor Training Course Completion

- Degree in Mechanical Engineering

- Diploma in hvac and refrigeration

Chad Bracken

General Manager Reactor Services

Chad has joined our team to head up reactor services. Chad has a wealth of experience supporting clients to achieve their outcomes, ensuring the plant is up and running efficiently and effectively. Chad and his team are the people to go to for expert support during a refueling program.

- Field Services Leadership, Supervision, Management, and Project Management 19+ years, with 17+ of those years in the Nuclear Industry successfully completing 135 assignments, 102 of them being outage support at customer sites (2007- present)

- Business Development, Process Improvement, and Strategic Planning

- Project Management over Augmented Reality Application Projects and Training Development

- Project Management of Outages and Dry Fuel Storage/Dry Cask Storage Campaigns

- Westinghouse – Motor, Pump, Seal Specialist, and Advisement

- Westinghouse – RCPM RVI Specialist

- Industrial Pump, Motor, and Seal Specialist

- GE – RST, IVVI, Vessel Tech, and Under Vessel Qualifications/Experience

- Reactor Head Replacement and Modification Projects

- Reactor Services – Head Area Maintenance, Reactor Disassembly/Reassembly, Refuelling Support Operations, Steam Generator Primary/Secondary Manways, and Pressurizer Manways Support.

“Powerhouse Resources provided support through the Spring outage at Oconee with expertise to support the inhouse skills during the instrument tube fitting.

We provided key personnel to compliment the in-house team and assist with skills that were not currently present. The project’s success led to increased work and support in the planning, preparation, and delivery of their next outage in the Fall.”

Duke Energy - Oconee Nuclear Station

03/25/24 ongoing

“NPPD retained Powerhouse at their Cooper plant to provide Outage Pump Support. We provided this service and during the rebuild of the Condensate Booster Pump it was discovered the Impeller had significant cavitation damage. It was decided to install a new impeller which would require off site balancing, in a two-week turnaround.

During the downtime, Powerhouse Resources supported a short-staffed Mechanical Maintenance team in areas not typically provided during the outage. With the team’s knowledge of Cooper Station and BWR plant design we were able to help perform PM’s on various plant equipment and supplement Cooper’s turbine and electrical teams.

This created a stronger bond and trust with the customer, while showcasing our skills and commitment to the plant.”

Cooper

October 2022